What is IC testing?

IC testing is to use relevant electronic instruments (such as multimeters, oscilloscopes, DC power supplies, ATE, etc.) to test the circuit functions and electrical performance parameters of the IC. The test items generally include: DC parameters (voltage, current), AC parameters (THD, frequency), functional tests, etc.

Why do IC tests need to be conducted?

IC testing is to detect the defects of IC function failure and performance degradation due to factors such as imperfect design, manufacturing process deviation, wafer quality, environmental pollution and other factors in the design and manufacturing process of IC. Analyzing test data, finding out the cause of failure, and improving design and process to improve yield and product quality are critical links in the IC industry

Introduction to finished product test (FT: Final Test)

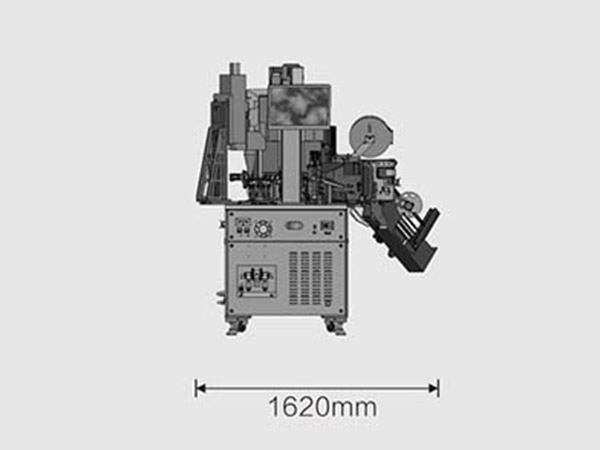

Finished product test: After the wafer test, the wafer is packaged with epoxy resin or other materials through a series of packaging processes such as cutting, bonding, wire bonding, and plastic packaging to become a separate IC. , And then use the test machine (ATE), Loadboard, manipulator (handler) to test the electrical parameters of each IC, and screen according to certain specifications, and distinguish the process of good and bad IC.