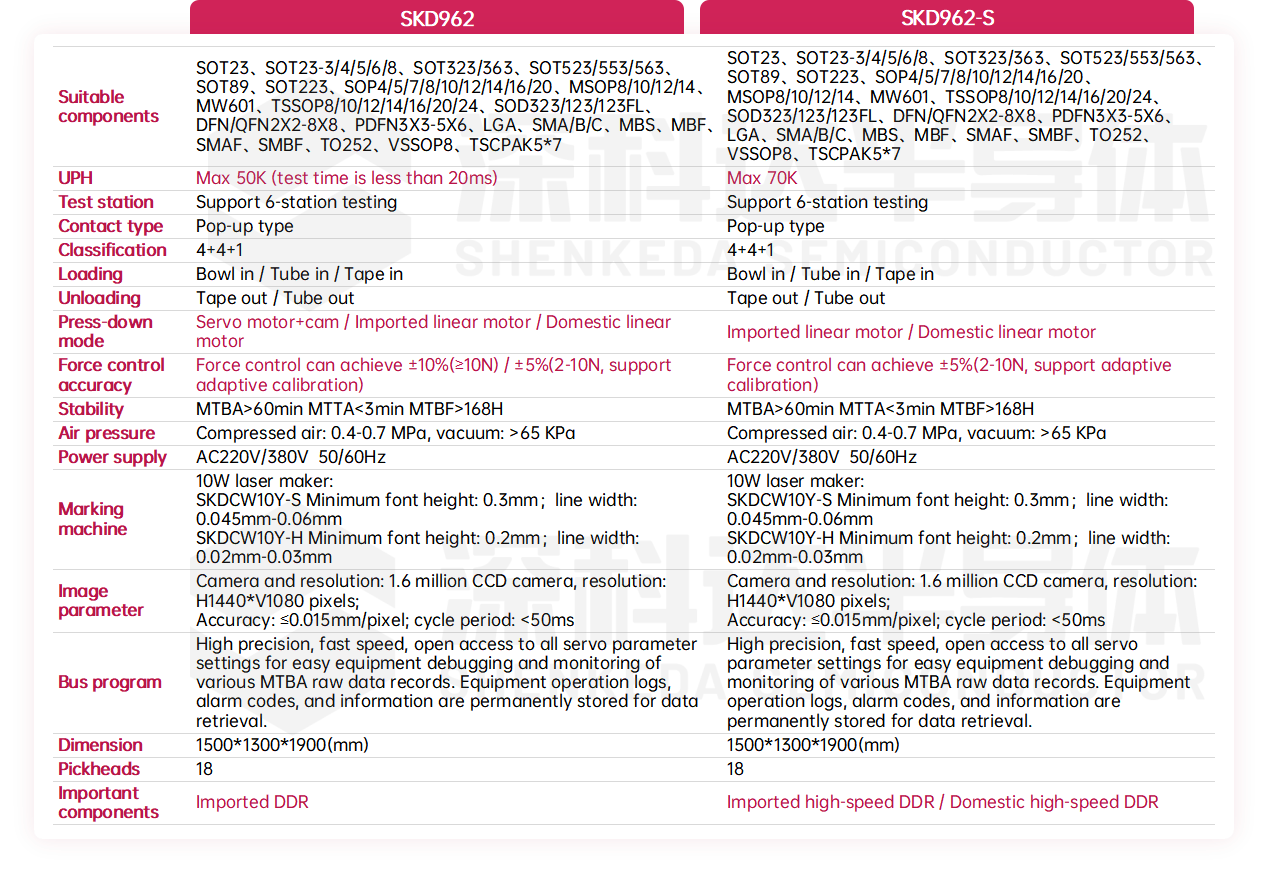

SKD962/SKD962-S Turret Test Handler

SKD962 is applicable for taping of discrete devices, IC devices, etc. It has high-speed test marking and taping capability and adopts high-precision DDR to ensure stable performance and high UPH output. Integration of marking system and vision system brings customers high quality product output.

● Pickheads with shielding and automatic height correction functions.

● Automatic onload: bowl in/ tube in/ tape in.;

● Testing: up to 6 electrical test stations, and one 3D inspection station. highly efficient orientation aligner and inspection of optical and electrical performance.

● Main turret: main turret with 18 pickheads driven by servo motor.

● Orientation aligner: precise positioning and commutation of the product, positioning tolerance ≤ 0.005mm, directional accuracy up to 0.1 degree.

● Marking: laser marking, vacuuming, vision inspection, and other functions can be completed on the marking station, which accelerates the marking speed.

● Tape out: in addition to automatic taping, it also has an automatic replacement function and sealing vision inspection.

● Tube out: It has the function of automatic pipe replacement.

● Supports automatic cleaning of the air path and automatic detection of the suction nozzle vacuum.

● The core components such as the vibration disc and the test base are all fully self-made.

|  |  |

Test station has poka-yoke function: the test station is equipped with stacked material detection, to eliminate the quality problems caused by jamming material; each test station has color and hardware poka-yoke. | The taping station adopts the new rail-type structure, which is simpler to use, more efficient, stable, with lower failure rate. It can be optionally equipped with vision inspection function after sealing. | The vacuum of the main turret is supplied by the upper and lower split air discs, which is simpler in structure and maintenance. |

Parameter Information

Scan to add WeChat