SKD308TB TRI-temperature Pick&Place Test Handler

SKD308H Pick&Place Test Handler is applicable for testing and sorting MSOP、QFN、DFN、LQFP、LGA、BGA、CSP and other products with specifications ranging from 2x2 to 110x110, meeting the requirements for both room temperature and high-temperature testing and sorting, while delivering high-quality product output for customers.

● Taking and discharging mechanical arm: Y-axis is double-sided drive mode; Z-axis motor independent control, equipped with 2X4 taking and discharging nozzle, X Pitch variable. The nozzle module adopts the span beam design, the center of gravity is stable, not easy to deform.

● Pressure measuring module: equipped with precision floating head and socket stack sensor, automatic calculation of pressure measurement, up to support 120 kgf.

● Shuttle module: XY two directions are equipped with sensors, accurately detect whether the shuttle car is stacked or not flat, protect materials; The unloading shuttle car has the function of return temperature heating.

● Temperature control system: Test TJ: ±2℃; Preheating tray/Shuttle: ±3℃; TC: ±1℃; 200W@ -55℃/300W@ -40℃/850W @ 25℃/1150W@ 85~150℃ / 200℃(Optional).

● Plate module: feed plate is equipped with motor screw, it is more convenient to adjust when using different thickness plate.

● Testing institution: supports four test modes: single site, two sites(1x2), four sites(1x4, 2x2), and eight sites(2x4).with automatic calibration, automatic calculation of pressure measurement, and socket stacking detection functions .

●Front and rear configuration display touch screen and key panel, support to connect a variety of brand testing machines.

|  |  |

The Y axis of the loading and unloading suction nozzle is designed with double linear guide rail and double power drive, which has long service life, high precision and more stable long-term operation. | The special pneumatic floating pressure head can automatically calculate the pressure according to the number of IC feet / balls. | The test arm Y-axis independent motor control can better achieve position control. |

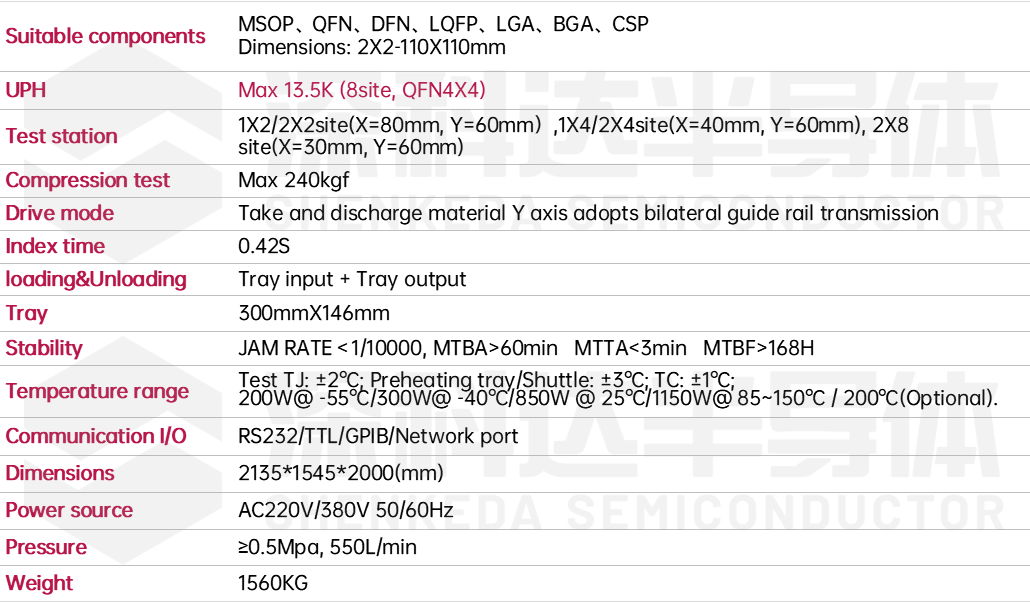

Parameter Information

Scan to add WeChat