SKD811H Gravity Test Handler

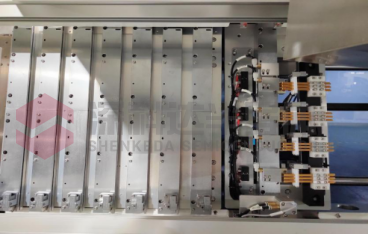

SKD811H gravity test Handler is a fully automatic that is designed for the testing of TO series packaging power devices.It has series connection of many test stations, which integrates insulation testing, conventional electrical performance testing, laser marking, brush dedusting, visual inspection and other functions.

● Loading: automatic double-tube in, automatic tube replacement.

● Equipped with normal temperature and high-temperature testing workstation.

● Preheating device: heating temperature ≤ 175°, high efficiency preheating mechanism (accuracy ±3℃), with rapid cooling performance.

● High-temperature test components: 4 high temperature test stations, heating temperature ≤175°, test stations are equipped with insulation function(accuracy ±3℃).

● Material separater level: driven by sever motor,the sub-shuttle blocking cylinder adopts the way of lower air intake, the mechanism is light, the operation is more stable and accurate.

● Offload: automatic tube out, which can be setted to red and white pipe to distinguish between good and bad products effectively.

● PLC control system, friendly man-equipment interface, the interface can be real-time display in the production of each product in tubes quantity, UPH, fault location, causes, treatment methods and other functions.

● Optional: Marking station, 2D visual station.

|  |  |

The number of test stations can be compatible with the polarity test requirements of multiple products at one time. | Unique material test positioning switching mechanism, improve efficiency, convenient maintenance. | The block Tcylinder of the split shuttle adopts the way of lower air intake, the mechanism is light and the performance is improved. |

Parameter Information

Scan to add WeChat