SKD610 Tray To Reel Converter

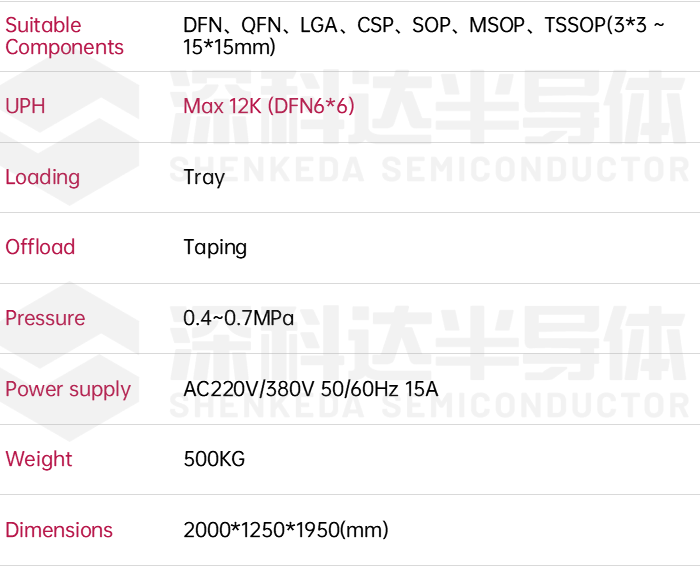

SKD610 is a tray-to-reel converter with AOI inspection, featuring tray feeding and automatic variable-pitch nozzle pickup for taping. It includes a multi-station imaging system to ensure high yield in taping. It can accommodate various package sizes such as DFN, QFN, LGA, CSP, SOP, MSOP, TSSOP(3x3 to 15x15mm).

● Mark Inspection Vision (two-dimensional mark inspection) can recognize, duplicate code imprinting, imprinting strokes broken and extra strokes, imprints beyond the plastic seal.

● The product direction judgment station can judge the materia’ s direction, lead deformation, character recognition, suction nozzle empty material.

● In Pocket Vision can inspect plastic seal body breakage, contamination, cracks and other bad products (visible to the naked eye).

● Visual inspection of the carrier’ s bottom to inspect the damage, depression and bad creases at the bottom of the carrier.

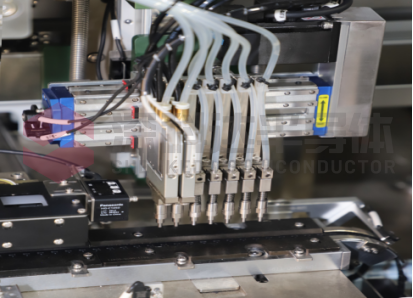

● Product transfer: 7-station variable distance fetching manipulator.

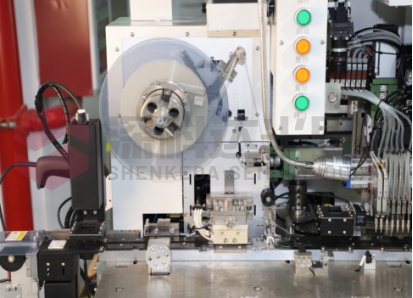

● Taping: It is adopted with open carrier track , which can meet the carrier’S taping function of different specifications.

|  |  |

With multiple groups of visual inspection work, it can detect 2D products, seal indentation detection, damage detection of carrier belt, etc. All-round guarantee of quality production. | Material handling components are modularly designed for high precision and speed, with independent upper and lower functions for automatic replenishment. And has independent up and down function, can easily achieve automatic feeding function. | The adhesive film component is motor-controlled, facilitating both taping and detaping simultaneously through forward and reverse rotation, with an alarm for insufficient cover tape. |

Parameter Information

Scan to add WeChat