SKD936H Turret Test Handler

SKD936H high temperature turret test handler is applicable for discrete devices, IC devices and other products with high-temperature testing needs, adding high-temperature testing capability on the basis of the original room-temperature performance to ensure stable performance. It is suitable for normal and high temperature test sorting and classification of PDFN/DFN/ MSOP/SOT/SOP/SOD/TO/SMA/B/C and other components.

● Test components: 1-4 stations of high temperature(optional)+room temperature, heating temperature ≤180°(high temperature test comes with insulation design).

● Temperature control accuracy: heating temperature ≤180°, temperature control accuracy of ±3℃, PDFN5*6 as an example can be pr+eheated at the same time 96 pieces of material.

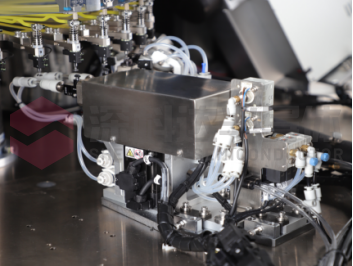

● High temperature auxiliary tower mechanism: the high temperature test is directly conducted on the high-temperature auxiliary tower, ensuring precise temperature control. At the same time, the inlet and outlet are equipped with anti-collision sensing devices;

● Cooling auxiliary disc mechanism: utilizing vortex tubes for cooling, it takes only 30s to reduce the temperature from 125°C to 28°C;

● Automatic feeding(bowl in): bowl in, loading speed is fast and stable.

● Main turret: the main turret is equipped with 36 pickheads driven by DDR motor, which can accurately send the product to the center of each station through the adsorption of the pickhead.

● Orientation aligner: accurate positioning and commutation of the product, positioning tolerance ≤0.005mm, directional accuracy up to 0.1 degrees.

● Marking: the marking station can complete laser marking, vacuuming, marking vision inspection and other functions, greatly speeding up the marking speed.

● Tape out: in addition to automatic taping, it also has an automatic replacement function and sealing vision inspection.

● Vision inspection function after sealing(optional).

|  |  |

Sub-turret heating device, tested on a heating plate, with high accuracy of temperature control, with color poka-yoka. | Flip components to adjust device orientation. High speed and simple structure. | Cooling sub-tray adopts vortex tube for a quicker cooling. |

Parameter Information

Scan to add WeChat