SKD936H Turret Test Handler

SKD936H high temperature turret test handler is applicable for discrete devices, IC devices and other products with high-temperature testing needs, adding high-temperature testing capability on the basis of the original room-temperature performance to ensure stable performance. It is suitable for normal and high temperature test sorting and classification of PDFN/DFN/ MSOP/SOT/SOP/SOD/TO/SMA/B/C and other components.

● Mark inspection vision (2D mark inspection) recognizes and recodes marks, broken and redundant mark strokes, and marks that are outside of the plastic seal.

● 3D5S can detect product size and integrity; it can also detect pin length, standoff height, offsets, pin width and pin spacing.

● In pocket vision (in tape) detects defective products (defects visible to the naked eye) such as broken, contaminated and cracked plastic seals.

● Product transfer: main turret has 36 vacuum pickheads. Sub-turret with clamping mechanism 20 pc;

● Pickhead feature shielding and automatic height correction functions.

● Can be connected to a variety of brands of tester, software independent property rights, the use of key switches, standard keyboard for operation and data input, with workstation interlock function.

● Orientation aligner: accurate positioning and commutation of the product, positioning tolerance ≤0.005mm, directional accuracy up to 0.1 degrees.

● No. of testing stations: up to 8 stations for elastic clamping with high testing accuracy.

● Packaging: TO220, idle UPH ≥11k(no testing or testing and marking time ≤120ms).

|  |  |

The sub-turret station adopts a large disk surface and multi-station method to improve marking efficiency and take into the large package products. | The testing station on the sub-turret utilizes clamping to meet the testing needs of different large packaged products. | The tube sorting BIN adopts servo motor to control the screw and slider, with accurate positioning, high speed, high efficiency, and high number of tube-sorting. |

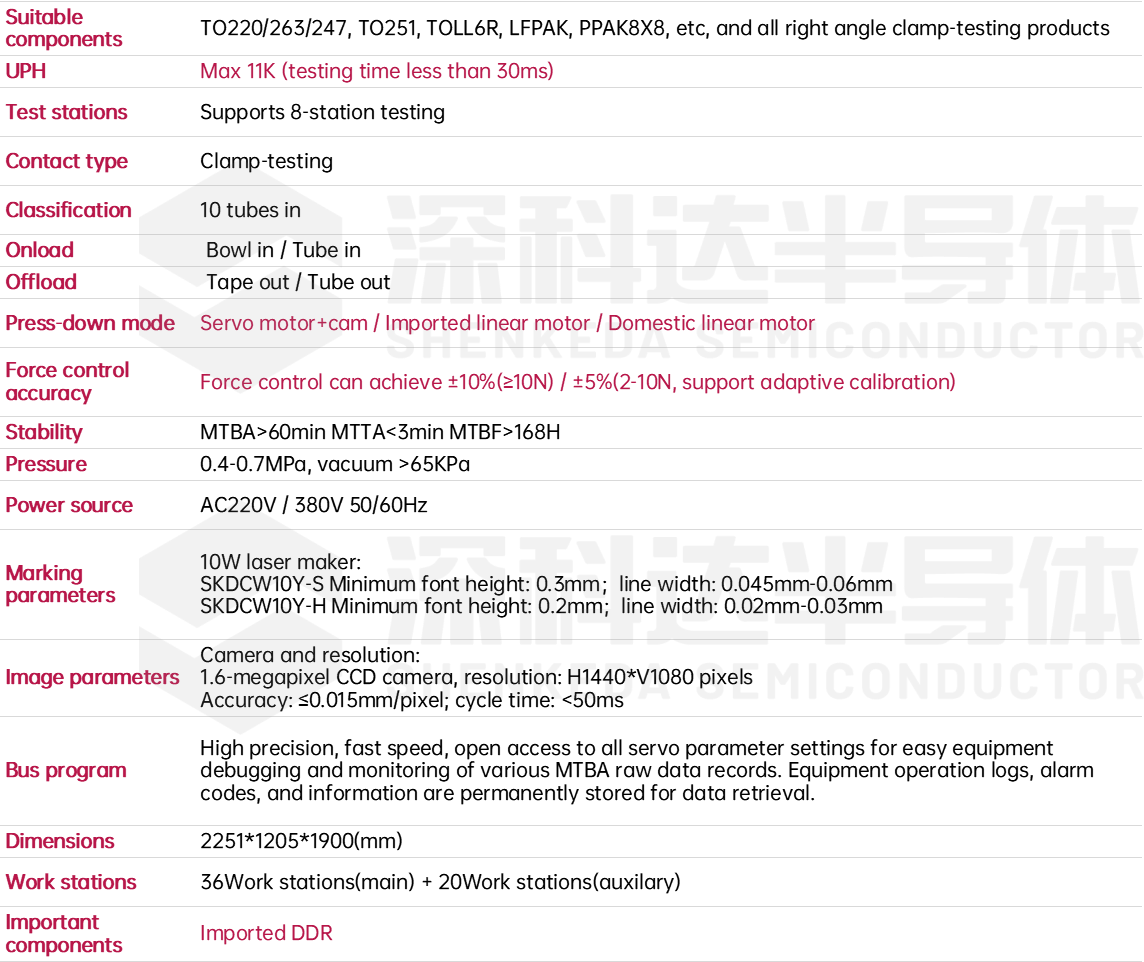

Parameter Information

Scan to add WeChat