SKD936L Turret Test Handler

The SKD936L turret test handler is utilized for the testing, visual inspection, and taping of light-sensitive series components. It employs high-precision direct drive rotary (DDR) technology to ensure consistent performance and high units per hour (UPH) output. The machine integrates three types of tests—light source, air void, and gray card—thereby delivering high-quality product output to customers.

● Supports simultaneous testing of up to 9 stations, enhancing the UPH of the machine for products with long testing times.

● The suctioProduct Advantagen nozzles have shielding and automatic height correction functions.

● Automatic feeding (with a vibrating disc device): The vibrating disc feeds materials quickly and stably.

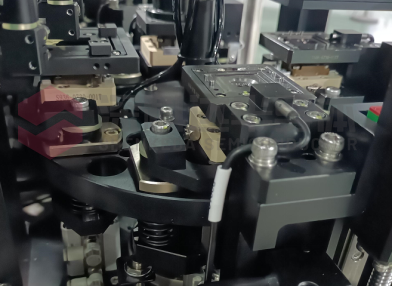

● Main turntable: The main turntable is equipped with 36 suction nozzles driven by servo motors, which can precisely deliver products to the center of each station through suction.

● Alignment/rotation device: Precisely positions and rotates products, with a positioning error of 0.005mm and a directional accuracy of 0.1 degrees.

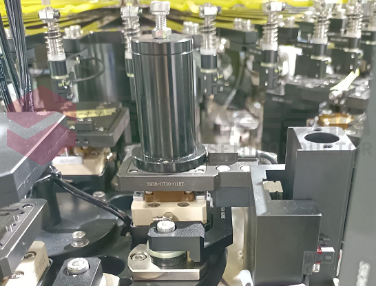

● Marking disk mechanism: The marking disk can perform laser marking, dust collection, and marking visual inspection, significantly increasing the marking speed.

● Taping component: Besides simple automatic taping, it also has an automatic replenishment function.

● Post-sealing image inspection function (optional).

|  |  |

Air test station, material and pressure plate floating connection, automatic alignment, accurate test position | Gray card test station, gray card to material distance automatic adjustment, easy to operate | Light source test station, darkroom seal is good, prevent external light interference, high repetition accuracy |

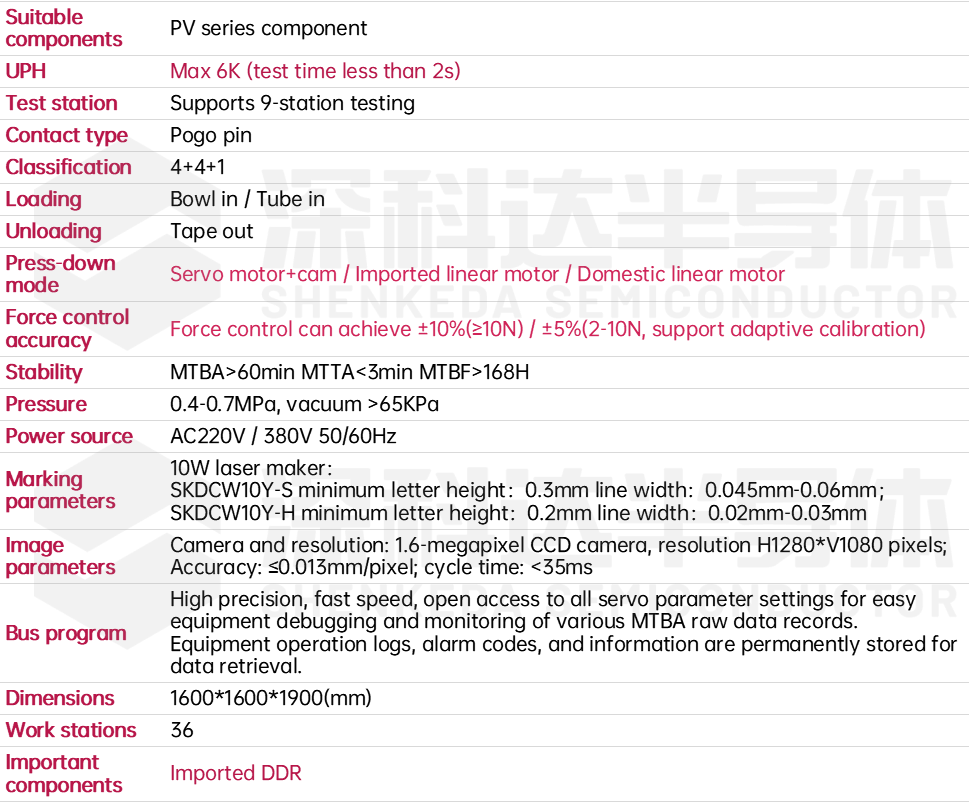

Parameter Information

Scan to add WeChat