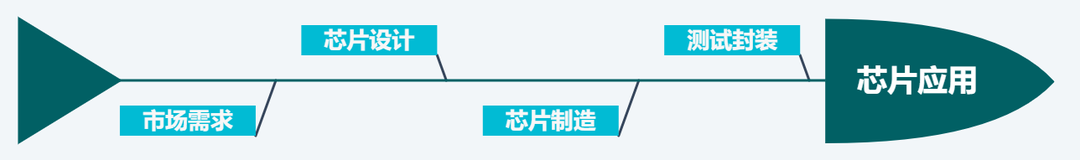

'Where is it made' and 'who designed it', packaging and testing are ignored. "

In the huge chip industry, chip testing is often ignored because it is in the middle and back end of the industry chain

But in fact, the production process of semiconductor chips is very complex, and any process error may lead to a large number of unqualified products, and have a significant impact on the performance of terminal application products, so chip testing is extremely important

01 Test itself is design

As we all know, the core of semiconductor industry is chip design. Because the design company owns the intellectual property of the product and can decide what supply chain to serve it, the entire industry chain serves the chip design company

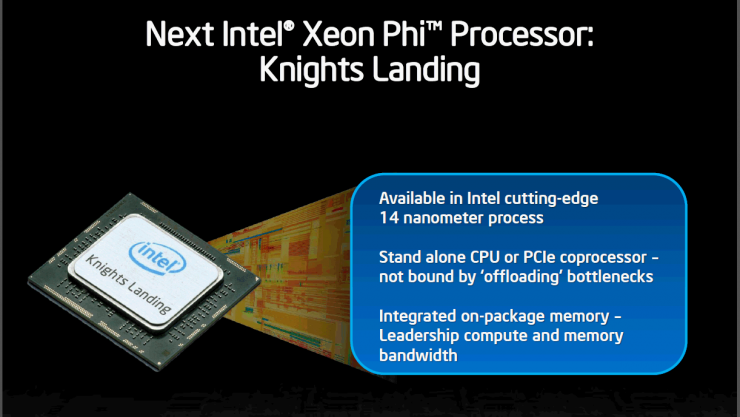

As the products enter the era of high-performance CPU, GPU, NPU, DSP and SoC, more and more modules are integrated inside the chip, and the failure modes in the manufacturing process are also increased accordingly, and the importance of chip testing is increasingly prominent

The following is a basic flow chart of the project of the chip design company. We can clearly see that from the market demand to the production of the product tap out, each link is marked with relevant considerations for testing. From the generation of test architecture and test mode to the synthesis of various noise/delay/failure modes, the test pattern will be generated, and finally the finished product test will be conducted to analyze the test data, so as to analyze the failure mode and verify the research and development

Therefore, testing itself is design, and it needs to be designed at the beginning. For design companies, testing is no less important than circuit design itself

02 Improve the rate of good products, reduce costs and increase efficiency

In chip competition, yield is the key

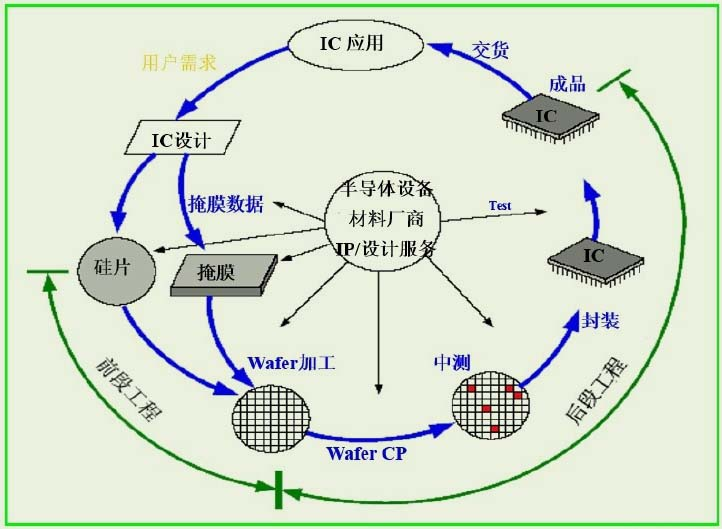

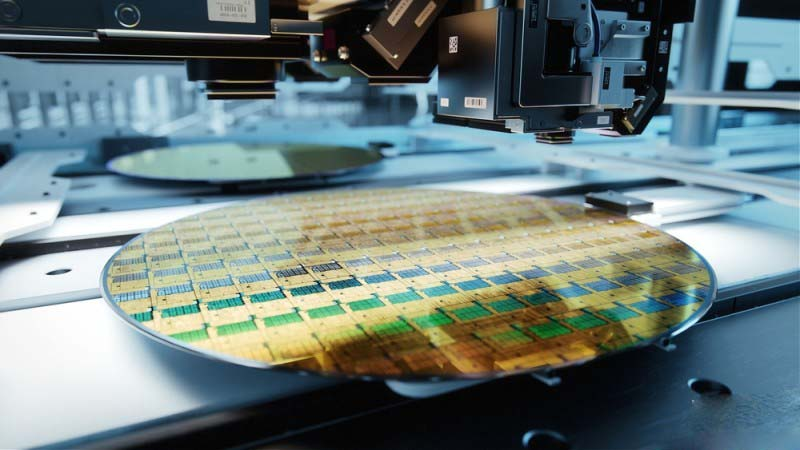

Chip testing runs through the entire industry chain and needs to be tested from beginning to end. In the process of wafer design, a lot of design verification needs to be done. In the process of wafer manufacturing, after each key process is completed, some index tests need to be done

In each test stage, the earlier the problems of these chips are found, the lower the cost will be, and more meaningful test data will be fed back to the design and manufacturing side, so as to effectively analyze the failure mode, improve the design and improve the manufacturing yield. If the problem of the chip is not completely found at all stages, the loss will be very large when the chip is finally used in the product

03 Chip test classification

Chip testing is mainly divided into two categories: sampling testing and full production testing

Sampling test mainly includes verification test, reliability test, characteristic test, etc. in the design process

Full production test refers to the process of picking out the defects and separating the good products from the defective ones. The production full test is divided into CP (Circuit Probing) test and FT (Final Test) test at different stages of the chip test, that is, the Wafer (CP test) of the whole wafer and the Chip (FT test) of the single chip after the test package

Among them, FT test, as the last pass before the chip leaves the factory, has attracted the attention of major manufacturers

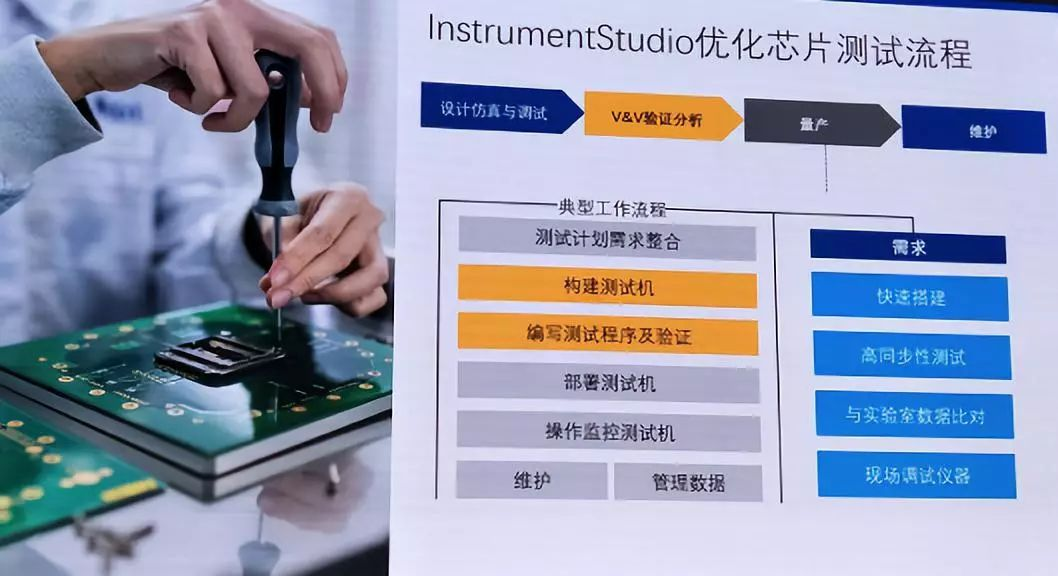

04FT test solution

FT test is mainly to solve various uncertain factors, find out whether there are problems such as excessive power consumption and high temperature during chip operation, and help customers find problems and improve the output of finished chips by extracting data and feedback to customers

Based on the differences of chip types, the test nodes in the chip packaging process are also different, and the test plans and test procedures are also different, so the finished product testing is more inclined to provide customized services for customers

Shenkeda Semiconductor is customer-oriented, customizes semiconductor testing and sorting solutions for customers, helps customers reduce production costs and improve capacity preparation, and strictly observes the last pass before the chip leaves the factory. Benefiting from rich industrial experience, the team can quickly and accurately grasp all kinds of problems encountered by customers in packaging, testing and quality inspection and provide solutions that can meet their needs in the process of communication with customers. The highly competitive service and value make Shenkeda Semiconductor win the trust of many customers along the way, establish a good long-term cooperation relationship, and become a high-quality choice for semiconductor test manufacturers in equipment procurement