SKD990/SKD990-S Turret Test Handler

SKD990 turret test handler is applicable for testing and taping mini semiconductor components. It employs high-precision components and DDR to ensure stability and high UPH output. The integrated marking and vision systems deliver high-quality product output to customers.

● The pickhead has the function of shielding and automatic height correction.

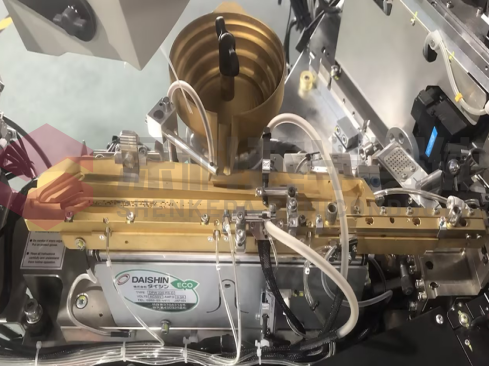

● Automatic onload(bowl feeder): Materials can be put on 3K-5K at one time.

● Inspection: product direction identification can choose the way of optical identification or electrical discrimination according to the characteristics of the product.

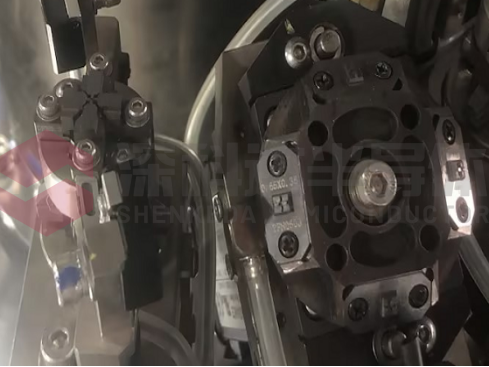

● Main turret: main turret with 18 pickheads driven by servo motor, and the products are accurately sent to each station center through the adsorption of pickhead.

● Orientation aligner: accurate positioning and commutation of the product, positioning tolerance ≤0.005mm, directional accuracy up to 0.1 degrees.

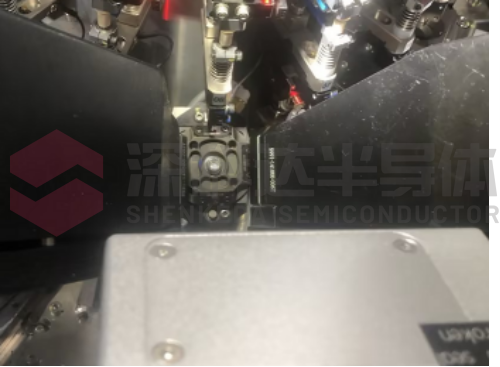

● Marking: the laser marking, vacuuming, marking vision inspection and other functions of the material surface are completed on the marking plate, which greatly speeds up the marking speed.

● Vision inspection function after sealing(optional).

|  |  |

The feeding mechanism is imported from japan to ensure better feeding. | There are four claw positioning before and after entering the laser station to ensure the smooth entry and exit of the laser disc. | Laser station marking adopts visual positioning, and the printing position is more accurate. |

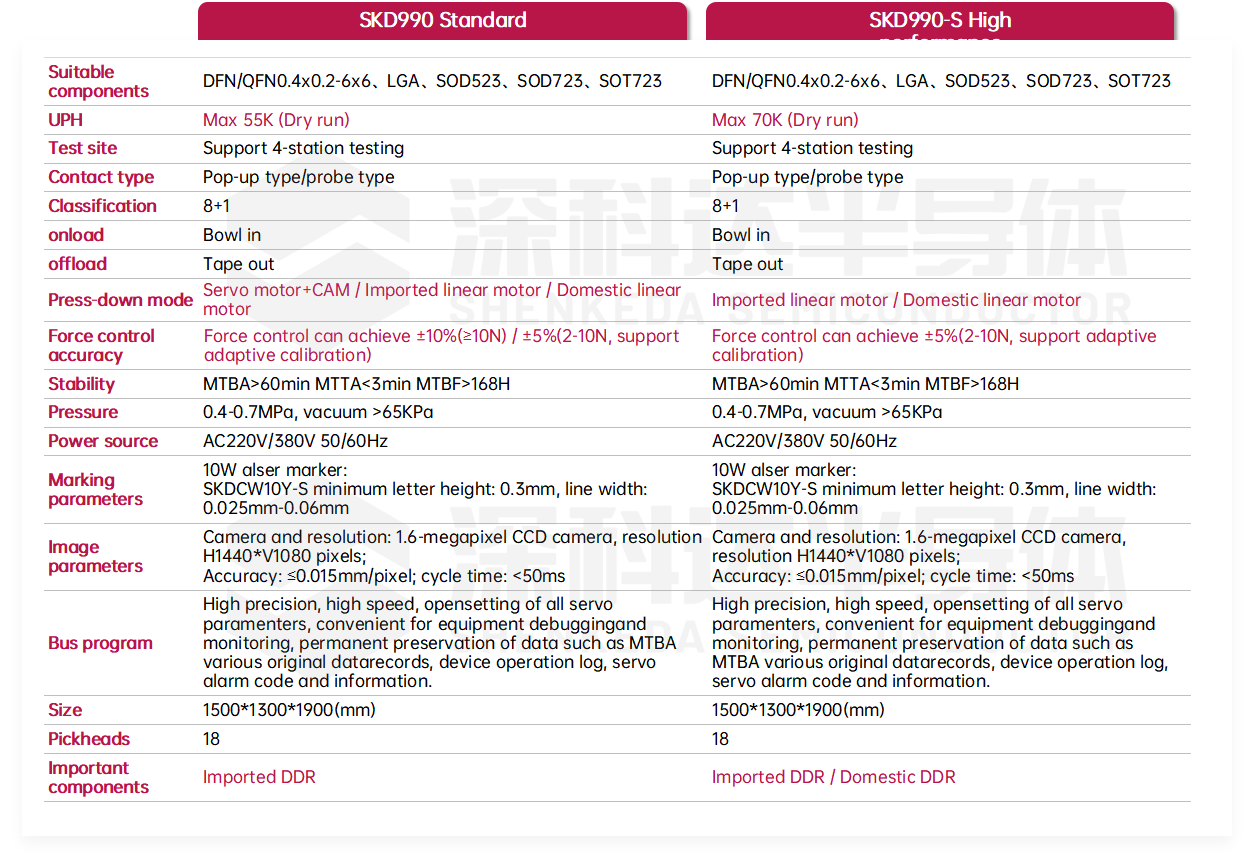

Parameter Information

Scan to add WeChat