SKD980/SKD980-S Turret Test Handler

SKD980 turret test handler is applicable for multi-function testing and sorting, it can meets the selection needs of more stations, flexible feeding mode, support flexible configuration of various discharge modes, can also meet more classification types and capacity needs of customers, and support the testing and sorting requirements of products with larger package size at the same time(TO220, TO263, TO252, etc.).

● Mark inspection vision (2D mark inspection) recognizes and recodes marks, broken and redundant mark strokes, and marks that are outside of the plastic seal.

● 3D5S can detect product size and integrity; it can also detect pin length, standoff height, offsets, pin width and pin spacing.

● In pocket vision (in tape) detects defective products (defects visible to the naked eye) such as broken, contaminated and cracked plastic seals.

● Product transfer: main turret has 24 vacuum pickheads.

● The vacuum pickheads have the function of shielding and automatic height correction.

● Can be connected to a variety of brands of tester, software independent property rights, the use of key switches, standard keyboard for operation and data input, with workstation interlock function.

● Orientation aligner: accurate positioning and commutation of the product, positioning tolerance ≤0.005mm, directional accuracy up to 0.1 degrees.

● Number of test stations:7(5+2QA) stations elastic pressure contact kelvin test station can complete the repeated test of the products to be taped, and the test accuracy is high.

● Packaging:TO252,dry run≥UPK=18k (no test or test marking times≤120ms).

|  |  |

The sub-turret station adopts a large disk surface and multi-station method to improve marking efficiency and take into the large package products. | The test station has two options of pressure test and clamp test, taking into account the test requirements of different high-current and high-voltage products. | The tube sorting BIN adopts servo motor to control the screw and slider, with accurate positioning, high speed, high efficiency, and high number of tube-sorting. |

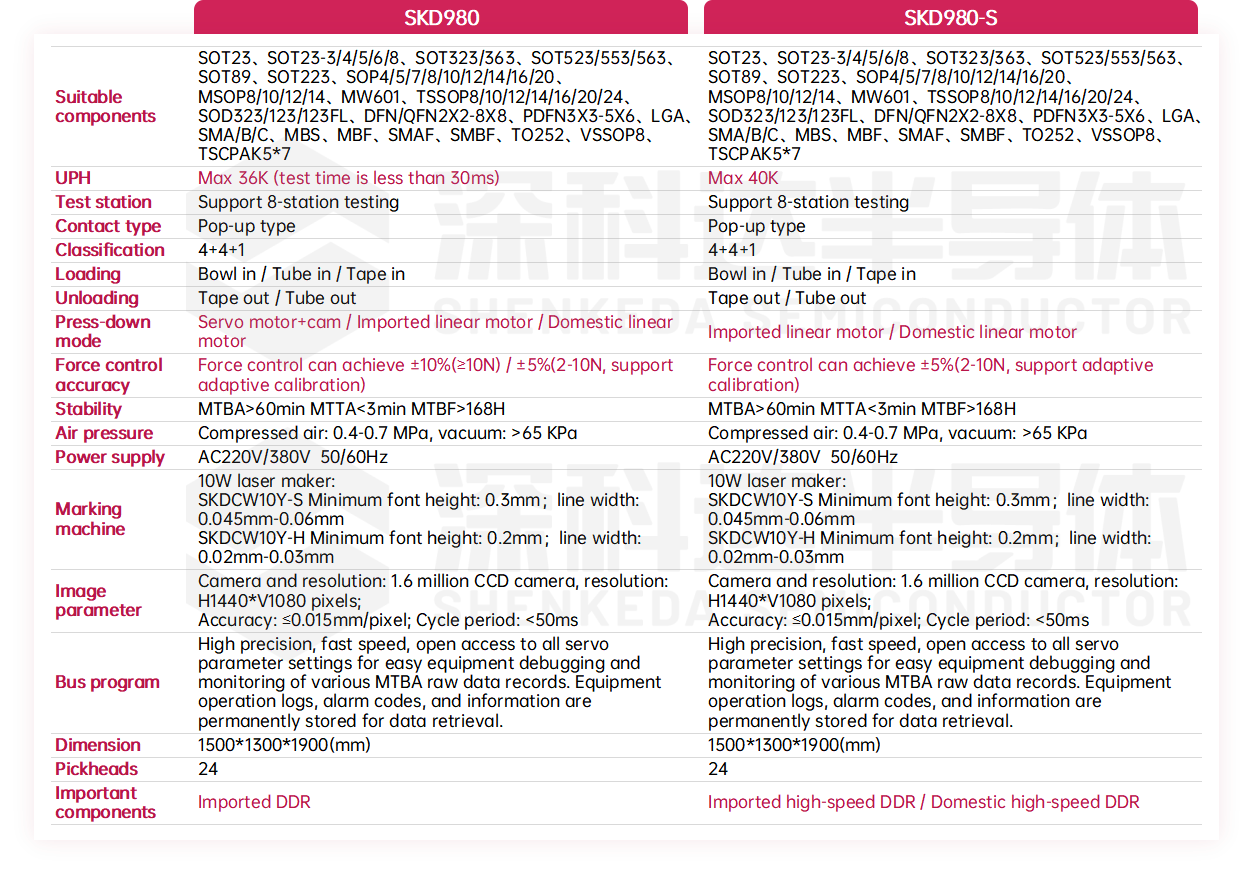

Parameter Information

Scan to add WeChat