SKD308TB TRI-temperature Pick&Place Test Handler

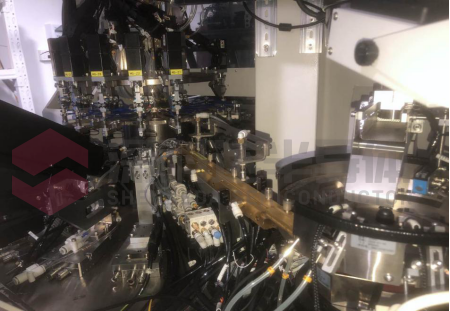

SKD308TB TRI-temperature pick&place test handler is applicable for multi-functional testing and sorting needs to meet customers' diverse testing needs. It is suitable for low/normal/high-temperature testing, sorting, and classification of MSOP/QFN/LGA/BGA/CSP(2X2-10X10 mm), and integrates imaging systems to yield high-quality product output to customers.

● Loading and unloading nozzle: 2X4 mode, the nozzle can be edged in the X direction, the Z-axis motor of the nozzle is independently controlled, and the Y-axis direction is a bilateral drive mode.

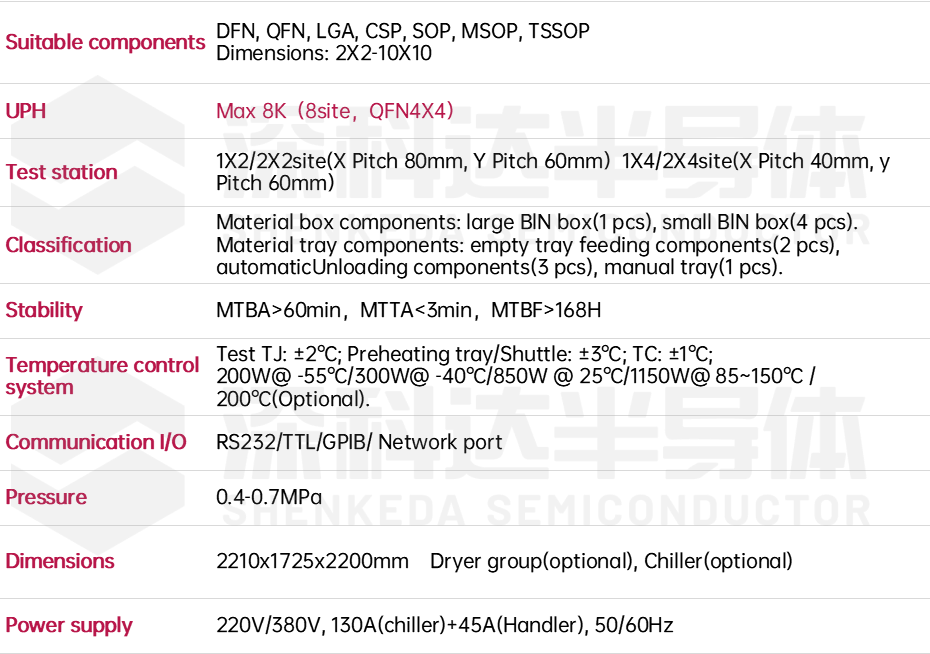

● Temperature control system: Test TJ: ±2℃; Preheating tray/Shuttle: ±3℃; TC: ±1℃; 200W@ -55℃/300W@ -40℃/850W @ 25℃/1150W@ 85~150℃ / 200℃(Optional).

● Plate changing manipulator: clamping method, safe and reliable, and also has automatic pull-up function when power fails.

● Testing institution: supports four test modes: single site, two sites(1x2), four sites(1x4, 2x2), and eight sites(2x4).with automatic calibration, automatic calculation of pressure measurement, and socket stacking detection functions .

● Automatic cleaning function: equipped with a cleaning disk assembly, the device automatically cleans the probe after the number of tests reaches the set value.

● Can be connected to multiple brands of testing equipments, has independent software property rights, and supports RS232/TTL/GPIB and other communication methods.

|  |  |

Vibrating plate loading, top image configuration, 3D5S , polarity test (optional), rich configurations and powerful functions. | The Unloading structure is equipped with a material box (one large and four small, optional) and a material tray structure, making it applicable to a wider range of scenarios. | Cross-feeding reduces the waiting time for mechanism actions and improves efficiency. |

Parameter Information

Scan to add WeChat